Lasers

I have had an interest in electronics from as far back as I can remember, however still vivid in my mind is when my interests in lasers commenced.

In early 1990, my aunt and uncle had given me their old Marantz model CD-44 CD player, which was not working too well, however this was exciting as I had not yet seen inside of a CD player.

When I took the covers off, I was amazed at the build quality, however what took my immediate interest, at the heart of the unit was the laser pickup, my first real encounter with a laser.

The Marantz CD-44 utilised the highly prized Philips CDM1 Laser. From recent research in trying to confirm which model Marantz I had, I have found some interesting information on this optical unit. Today, the CDM1 can fetch well over $300.

It was off the back of experimenting with this laser that really began to push the desire to build a visible laser and spur on the studies in the field of lasers.

To read more about the Philips CDM1, check out the following links:

Dutch Audio Classics:

The evolution of the Philips mechanism

Hi-Fi Advice:

Philips CDM mechanism

Update: At the time of writing this section in November 2020, I did not have any personal images of the CDM-1 or a Marantz CD-44, however, In late September 2024, I was able to secure two working units. Read more in Back to where it all began.

This first experience with a real laser, had started it all. From that point on, I began to obtain any literature and books about lasers and I found much of my time spent in the school library reading texts on the subject.

I also recall a number of movie references to lasers, one is James Bond, Goldfinger and the other was in Macgyver which I loved watching... still the classics on both accounts.

30 years ago, in October of 1990, I was venturing in the city and payed a visit to the number of electronics stores in York St Sydney, known as "Silicon Alley" (many which no longer exist) and asking if they had any available kits to build a laser. Although I was not able to find any available kits on the shelf, one of the staff had shown me a copy of the November 1990 issue of Silicon Chip, which he mentioned featured a project on building a laser. I had purchsed my first copy of Silicon Chip at the time.

Since building my first Helium-Neon Laser in 1990, I have gone on to collect a variety of lasers and laser systems and also a small collection of vintage lasers from the days gone by.

It was around 1997 / 1998 when I joined Ebay, opening up a source of lasers and laser instrumentation. By comparison today, many Helium-Neon lasers on Ebay are now very expensive.

I have a vast collection of Lasers, laser related equipment and parts, many I still maintain in my collection and others have since been moved on. I have in the more recent years, focused on collecting older vintage lasers where they have an interesting design which depart from how this are made today.

The following is a small list of lasers I have:

Helium-Neon Lasers and tubes with outputs in Red (632.8nm), Yellow (594nm) and Green (543nm). The largest output I have are 2, JDSU 1145P lasers which output 23mW.

UPDATE: Read more about the Elliott laser in the Laser Gallery, where a full write-up has been completed, together with new photos and detailed description of the optical configuration of the resonator.Vintage Spectra-Physics lasers including an SP124 and SP255s exciters, SP120 (no longer functioning), SP130 and the smaller Side-arm style plasma tubes. The SP124 had an output of around 4mW not long ago, however due to the soft seals its slowly fading away.

UPDATE: As of late September / October 2021, I had pulled out of storage an older Spectra-Physics SP-907-1 Laser, which is now producing >22mW

Read more about the work on this laser on my Spectra-Physics page.Argon-Ion Lasers including several smaller frame units from the NEC GL3030, Xerox / ALC 60x, Spectra-Physics 161/162 series, JDS-Uniphase 2000 series, and two ILT-5500 series. I have also had a number of Coherent I-90 based large-frame argon lasers, however these require 3-phase, water cooling to operate, not to mention also very heavy. With the progress of Semi-conductor laser technology, Argon Lasers have all but been made obsolete.

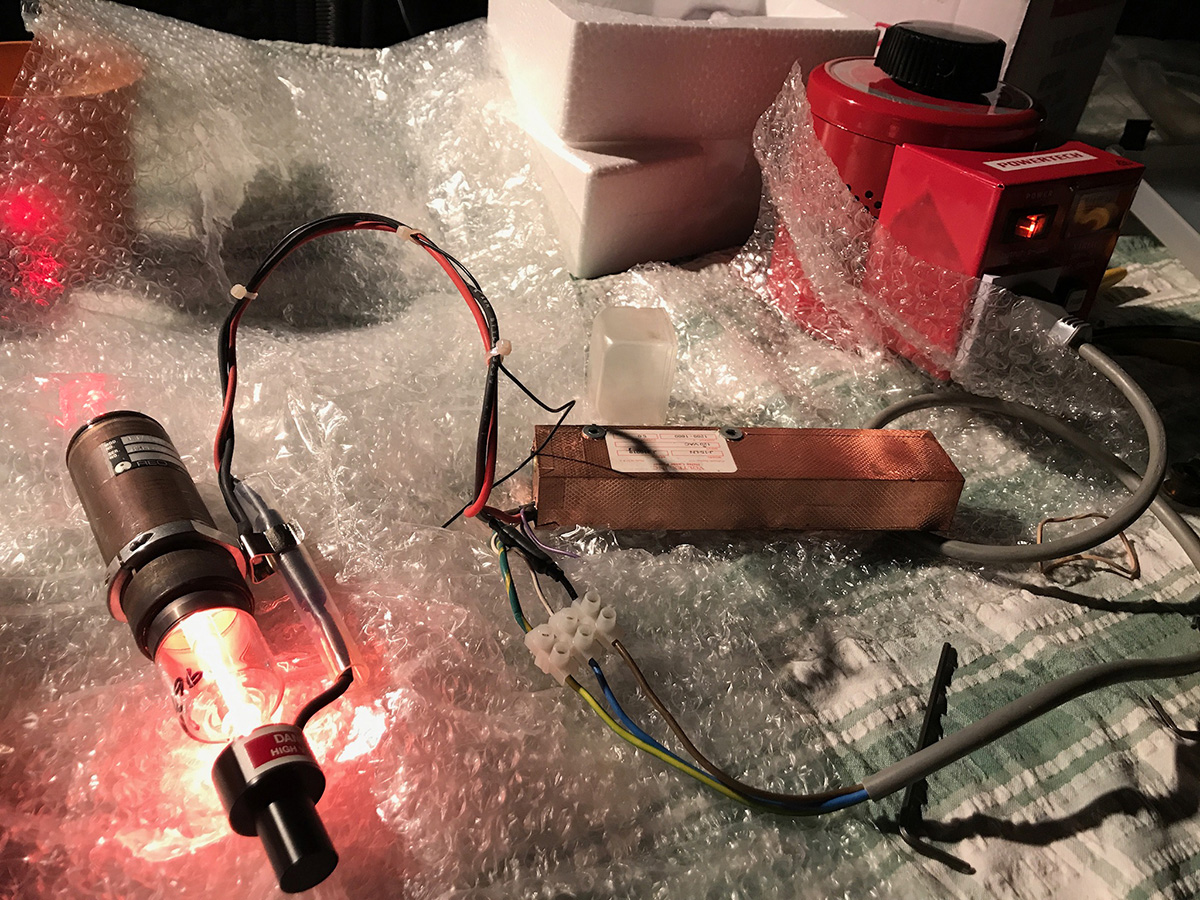

Copper-Bromide II Laser (an ex cosmetic treatment laser manufactured by Norseld, Australia).

Solid-State lasers including Laser Diodes, Diode-Pumped Solid-State (DPSS 532nm, 473nm & 560nm), ND-YAG and Ruby.

CO2 Laser Tubes.

Ex-medical Lasers Coherent 920 Photocoagulator / 599 Dye, 7900 ND-TAG, Ultima Argon Lasers.

In 2021, I completed a home-built Nitrogen laser and also commenced working with Nitrogen-pumped dye lasers. To read more about my journey on theses recent projects and more, please head over to my project pages, where I have written up my Nitrogen Laser project and also my work on Dye Lasers.

Over the many years, I have been fortunate to have been able to obtain several laser systems, which has given me invaluable experience with many different types of lasers.

One of my first pulsed solid-state lasers that I obtained, was the small ND:YAG lasers cavities which came out of the Coherent 7900 series ophthalmic lasers used for YAG Laser capsulotomy following cataract surgery.

Originally, the cavity was non-functional due to a failed flash-lamp, however I was able to repair the laser with the use of a Xenon flashlamp (which was of the same length as the original) from an old photoflash unit.

The result was successful and was able to obtain a working laser cavity which also was able to be powered from 4 'AA' batteries.

The cavity is small, measuring 112mm long x 48mm wide x 25mm high. The actual ND:YAG rod is 3mm x 80mm

This laser cavity was used to produce circular pinholes in aluminium with the use of an objective from a CD Player optical block.

The measured energy produce by the cavity is 118 millijoules.

Additional Laser related images and resources featured in our Laser Gallery.

The following projects are but a small selection of projects in which I have constructed over the years.

Most of my projects I still have in my collection.

Laser Pointer

The early 1990s, visible semiconductor laser diodes were a device of dreams, the thought of such small device, capable of producing a laser beam from a small input voltage. Remember, the domain of visible lasers in this era was that of gas lasers such as Helium-Neon lasers and Argon lasers which required high-voltage power supplies and for larger Argon lasers, 3-phase water cooling.

Early semiconductor lasers produced infrared light at 780nm (invisible) and being used in Compact-Disc (CD) players.

The thought of a visible output laser diode was very exciting, however early visible diode were very expensive, and the risk of damaging the diode by static and or too much current was high.

In 1992, visible diodes had started to become available as used surplus, however these were the early deep-red emitting diodes at 670nm, just prior to the availability of 650nm and later 635nm.

The design of my laser featured a 670nm 5mW laser diode. The diode mount / heatsink was constructed from turned aluminium stock and formed part of the front cap of the laser.

A small circuit was employed to drive the laser as well as give either continuous or pulsed operation.

A small rechargeable battery provided power for the laser.

I had taken the laser to school to demonstrate in one of our science classes, the science head teacher was very impressed with the laser and had approached me about building a unit for the school science department.

I had constructed a second laser, which was sold to the school on 6th May 1992.

Argon Laser Power Supply

On 16th November 1993, 27 years to the day of this writing, I had visited Oatley Electronics to purchase my first small-frame Argon Laser tube.

The laser was an NEC GL3030, removed from high-speed laser printers. The output from the laser was around 40-100mW depending on current. The output was in the blue at 488nm.

To power the laser, you needed a 3.2V filament voltage at around 10 to 25 Amps, and a Voltage of around 80VDC to 105VDC at 4 to 10A across the tube.

A high-voltage pulse is required to ignite the arc, typically the laser head had a high-voltage starter module which injected the pulse across the tube.

My first power supply was a simple but crude setup of a large 1kVA toroidal transformer which was manufactured for the purpose. The AC voltage was rectified to DC and filtered using 6 Electrolytic capacitors.

Current control was achieved by switching in or out a series of 100W, 1 Ohm resistors. It was a simple setup, but reliable.

My power supply was very useful at testing many Argon laser tubes including the ALC-60X, Spectra-Physics 161 series and the Uniphase tubes.

The American Laser Corporation Model 60X Argon laser has the option of a Littrow Prism in position of the HR, this allows selection of individual wavelengths through the adjustment of the angle of the prism.

Optical power is reduced in this configuration. Alternatively, a broadband HR can be installed, allowing the laser to output across the blue-green spectrum, and an increased output power.

Since the proliferation of Laser diodes, the Argon Lasers now see little use.

Dual-Colour Helium-Neon Laser Project

The dual Helium-Neon project came about more as an experiment to combine two different wavelengths together and generate a third colour.

Using a Red and Green laser, the resultant combined beam would be a yellow colour.

Analysing further, the lasers I used also featured a polarised output. I had come up with the idea to take advantage of the polarisation with the use a polarisation filter in front of the red Helium-Neon Laser, I would be able to control its power and therefore the ratio of red mix with the green.

A major design of the project was hand-making the optical mounts for the mixing optics, steering mirrors and the tube holding mounts.

The overall idea for the project was to use it as part of a laser display system, however this did not eventuate, and I had reused the power supplies for other projects.

AR-100 Laser Projector

The AR-100 was a project to build a basic laser projector for beam effects for laser shows.

A Spectra-Physics 161 Argon plasma tube was retro-fitted for this project and the laser was powered from my Argon power supply. The matching high-voltage starter installed also in the larger section.

In the front section, a small transformer, power supply, scanning motors and a wavelength selection filter were installed.

On the top cover, a large cooling fan and the control knobs to control the laser patterns, colour selection button and laser start button.

The construction took some time with the gluing of the external felt and making of the aluminium trim which were all cut by hand.

Helium-Neon Lab Laser

This simple little project came about when I had come into finding some small high-voltage power supplies that were able to run off around 7.5Volts.

The Helium-Neon laser tube came out of a Pioneer Laserdisc player.

I had built a small NiCad battery pack at the time and constructed a housing.

Recently this laser was refurbished with standard AA NiMh battery pack. The laser is still going strong.

CO2 Laser

In late 1999 I had embarked on a design for a flowing CO2 laser. I began to purchased components including optics, and other components.

My design was going to implement the use of a Neon Sign transformer for the power source, either 15kV/30mA or even a larger 15kV/60mA which I had acquired.

The following description has been re-written from my original notes, now 20 years on. Now looking back at the design, with my knowledge today on lasers, many things would have been designed differently, however this was my first experience in designing a working laser.

Plasma Tube Details

Initially, I had thought about a tube length of a 1,000mm, however, later, I had reduced the length to 800mm with consideration to the power I had.

For my tube, I chose a bore size of 20 mm ID and 24 mm OD. The larger bore would potentially generate more power, however in hindsight, the bore diameter potentially too large.

Optics And Adjustable mounts

The laser tube has an integral cooling jacket, and the ends of the plasma tube have been extended by 20 mm, which then mates with the copper bellow sections at each end of the plasma tube.

A bellow system is used between the glass plasma tube and adjustable mirror mounts. The bellows are made up of two copper adaptors, which then the copper bellows are soldered to form a complete part.

On the mirror side of the bellows, a brass plate is soldered, and four tapped holes made to allow mating with a larger (front) acrylic adjustment plate, which also has a milled section to accept an O-Ring and allow the mirror to seat. A top ring would clamp the mirror assembly together.

A second (rear) fixed plate forms part of the support structure and mounting points for the front adjustable plate, a set of tension springs would allow for mirror alignment and adjustment range.

The copper end sections would also server for the gas and electrical connection points.

Estimated power output

Although it is very difficult to determine due to the many variables involved, from my design using 1" optics, 20 mm bore, 800 mm length, and a power supply of 15 kV at 60 mA, an output from 20 watts up to 60 watts may be achieved, however this is going on commercial lasers of similar size.

Providing more voltage/current will give you higher output, until you reach a saturation point where the output will begin to decrease with further input (similar to a Helium-Neon laser).

Laser Graphics Projector

In 2002 I had embarked on another major project of building a full graphics laser projector.

The projector utilises the Cambridge Technology CT-6800HP series scanners, acousto-optic modulator (AOM) for beam blanking and an ILT-5500 Argon-Ion laser at its heart.

The laser scanning amplifiers were purchased as second-hand hardware from a major laser display company.

The project also featured a 488MHz FM transceiver to allow remote wireless control of the beam colour selector and a diffraction grating for beam effects.

LED indicators are used to indicate status, and visible through a glass window of the enclosure

All power supplies and associated control electronics hand built, and all housed in the optical enclosure.

The entire optical unit was housed in a fully sealed enclosure to protect the optics, and associated connections made via plugs in the housing.

The entire projector was housed in a full enclosure with a hinged top for service and access.

The laser was built and used in a local community and government initiative event in 2002.

Modern laser projectors are much more compact and now featuring full-colour solid-state laser sources (combined laser wavelengths). The days of the Argon Laser projectors are long over.

The following images of Cambridge Technology scanners including my CT-6210 scan set, and CT-6800HPs

In the early days of wanting to build a laser projector, high-end laser galvanometers were expensive and not easy to come by as not only did you require the scanners, but also the scanner amplifiers and also the digital to analogue converter (DAC) which took computer digital data and converted it to an analogue voltage level for the scanners.

Early entry into making a scanner set took some experimentation and some available simple techniques of using motors to spin a mirror that was mounted as a slight angle. A more advanced project added 3-motors and ability to vary the speeds of each motor to produce many interesting Lissajous patterns.

Another one of my projects took two DC motors and fed them using a SIN / COSIN signal. By varying the phase and amplitude of each of the 'channels' once would be able to produce some interesting Lissajous patterns.

Many of the early projects for lasershow display eventually were superseded once I was able to afford a full set of high-end laser galvanometers. At the time I also invested in a high-end laser show software and PC hardware which was used with my large Argon laser graphics projector.

In recent years I had purchased a small, cheap full-colour laser projector which features an RGB laser module and built in graphics. Mixed Red, Blue and Green lasers are able to produce some very nice and intense colours, leaving the Argon laser at 488nm in its tracks.

- Flavio Spedalieri -

Written: 18 November 2020

Updated: 30th April 2025

This Document Complies to W3C

XHTML 1.0 Strict Standards